How do we produce our

canopy tents?

From a selection of high-quality materials to best in class manufacturing, our products embody the best of decades of expertise for long-lasting canopy tents.

Our Textiles: The Technical Details

Our canopy tents are made using professional-grade fabrics with top of the line weatherproofing technology. Experienced seamstresses and tailors then transform these fabrics into Ecotent’s canopy roofs that you can count on regardless of the weather or occasion.

100 % waterproof fabrics

Our textiles have been tested according to the European standard EN 20811, which determines the water resistance of our canopy tents under hydrostatic pressure. Ecotent’s result: Our canopy tent fabrics are 100% waterproof, ensuring that you remain dry no matter the location.

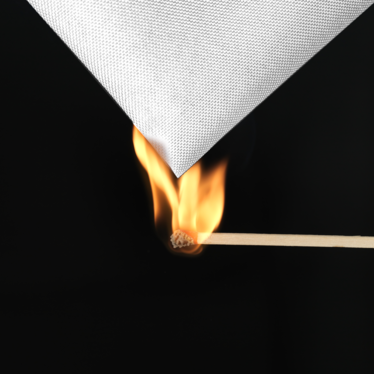

Fire-retardant textiles

Our Oxford 500D and Oxford 250D textiles have been tested and certified for fire resistance by the renowned institute Efectis Nederland BV. In accordance with the European standard EN 13501-1:2018, they have been assigned to the fire protection class B - s1, d0 and are therefore considered flame retardant.

Why is this important?

In order to be allowed to set up a pop up gazebo at certain events, especially public events, organisers usually require a certificate proving the fire resistance of the textiles, and this is exactly what you get when you buy an Ecotent® pop up gazebo. Of course, direct contact with open flames must always be avoided.

Textiles with UV protection

Ultraviolet rays can not only be uncomfortable because of the heat, they can also be extremely harmful to your health and seriously damage your products. Our textiles for pop up gazebos have a UV protection value of UPF 50+, the highest achievable value on the scale. This guarantees that you, your customers and your products will always be protected from ultraviolet rays! Of course we had this tested and our textiles passed this test with ease.

Lightfast colours

When we talk about the durability of our pop up gazebos, we also refer to the colour fastness of the textiles. In accordance with the European standards DIN EN ISO 105-B02 and DIN EN ISO 105-A02, our textiles have been given a blue scale of 4.5-6.5 out of a maximum of 8 and a grey scale of 3.5 out of a maximum of 5 marks. These standards specify a test method for determining the colour resistance of textiles of all types and in all states of processing. They are tested under artificial light conditions corresponding to natural daylight. Our textiles passed with flying colours even in prolonged sunlight.

European certificates of conformity and safety

All our textiles have been tested and certified for the most important conformity and safety certificates in Europe:All canopy tents are TÜV-certified (product certification).All materials used in the production of the canopy tents are REACH-compliant.

Further tests have been carried out by independent international bodies to prove the sustainability of our recycled fabric:Our “Recycling” fabric has been certified according to the applicable Global Recycled Standard by Control Union.